The Greatest Guide To Premier Aluminum Llc

The Greatest Guide To Premier Aluminum Llc

Blog Article

The Facts About Premier Aluminum Llc Revealed

Table of ContentsNot known Factual Statements About Premier Aluminum Llc Premier Aluminum Llc Can Be Fun For AnyoneEverything about Premier Aluminum LlcThe Facts About Premier Aluminum Llc Revealed

(http://peterjackson.mee.nu/where_i_work#c2475)Traditionally, a purchaser's key responsibility was to locate certified and responsive distributors. In some situations, purchasers thought that any distributor prepared to contractually fulfill the acquisition requirement was certified. However, making use of affordable and unqualified suppliers can create high quality concerns, and lost time and cash over time. To help you with the procedure, right here are some things to take into consideration when picking the right steel spreading distributor.

For instance, a business that just makes use of the investment casting process will try to sell you on why that process is best for your application. However suppose using the sand spreading procedure is best for you and your needs? Instead, look for a supplier that supplies a series of casting processes so the very best alternative for YOU is selected

If working with a single source for every one of your casting needs is very important to you, the supplier needs to be diverse in its capacities. When combined with other integrated abilities, this can assist streamline and press the supply base. When selecting the ideal spreading supplier, mindful consideration must be offered to quality, solution, and rate.

How Premier Aluminum Llc can Save You Time, Stress, and Money.

Customers progressively choose spreading distributors that have machining capabilities. If the casting distributor uncovers a concern throughout machining, the problem is resolved quicker with no disagreement over whose fault it is.

Issue or no, integrated machining streamlines the supply chain and lowers managing time and shipping price before the item makes it to the customer. What do you need from your spreading distributor? Are you searching for somebody to simply supply a metal part to your doorstep or do you require much more? If you do not have internal metallurgy competence, verify that the provider can supply guidance in selecting the appropriate alloy based on your details application.

Some factories are limited or specialized. Make sure the vendor can fulfill all your product or alloy demands to remove the need for multiple providers.

Premier Aluminum Llc Things To Know Before You Buy

Research study the vendor's website. Talk to a sales associate or company associate. Ask a great deal of inquiries. Visit their facility. Get an understanding of what they can do for you and if you can see on your own building a solid, mutual partnership with them.

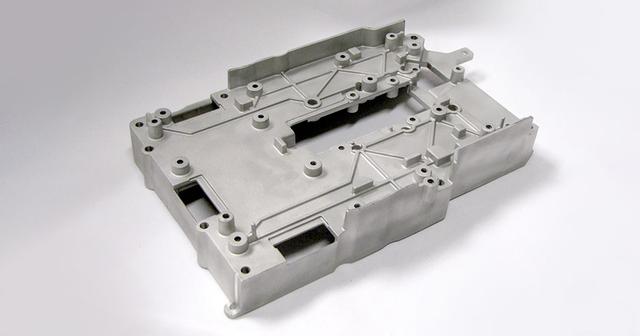

Aluminum is likewise light-weight and has great corrosion resistance, making it excellent for applications where weight and sturdiness are very important variables. Additionally, light weight aluminum spreading is an affordable technique of production, as it calls for less energy and resources than various other techniques. Iron spreading, on the various other hand, includes pouring molten iron right into a mold to create a desired shape.

Some Ideas on Premier Aluminum Llc You Need To Know

Iron casting is check out here likewise able to endure high temperature levels, making it ideal for usage in applications such as engine parts and industrial machinery. Nonetheless, iron casting can be a lot more costly than light weight aluminum casting as a result of the greater price of basic materials and the power needed to melt the iron. When choosing between light weight aluminum spreading and iron casting, it is essential to consider the details needs of the application.

In final thought, both aluminum spreading and iron casting have their very own distinct advantages and negative aspects. There are 3 sub-processes that fall under the classification of die casting: gravity die casting (or irreversible mold and mildew spreading), low-pressure die spreading and high-pressure die casting. To obtain to the completed product, there are 3 main alloys used as die spreading product to choose from: zinc, light weight aluminum and magnesium. Report this page